News archive 2015

Holzindustrie Schweighofer starts operations in its newest sawmill in Reci

Holzindustrie Schweighofer has started the operations in its newest sawmill in Reci, Covasna County. This project represents an investment of 150 million euro and will create 650 jobs directly in the sawmill and other 2,000 jobs in the region.

The new sawmill, whose construction started in December 2013 (with building permit no. 220 / 24.12.2013), spans over an area of 70 hectares and has an annual cutting capacity of 800,000 cubic meters round wood, sourced exclusively from sustainably managed forests from Romania and other countries such as Poland, Hungary, Austria, Croatia, Slovenia etc. Following this investment, Holzindustrie Schweighofer becomes one of the largest private employers in the region. Currently the factory hosts over 300 employees, but their number will reach 650 when the factory runs at full capacity. Also, drawing on past experiences from other sawmills, the company estimates that other more than 2,000 new jobs will be created in the region, in related industries, due to its cooperation with other firms. At the same time, Holzindustrie Schweighofer will become one of the main contributors to the state budget in Covasna County, as the new sawmill is expected to bring to the buget over 6.8 million euro per year in taxes.

At the same time, the new sawmill in Reci is an important project for the local community in Covasna County, which benefits from Holzindustrie Schweighofer’s support in several social projects in the cultural, education and healthcare sectors, following the model of the other locations in Romania where the company is active.

Holzindustrie Schweighofer clarifications regarding the report released by the Environment Investigation Agency (EIA)

A report carried out by the Environmental Investigation Agency (EIA), which analyzes the situation of illegal logging in Romania, presents a large number of false accusations based on inaccurate and tendentious information about Holzindustrie Schweighofer, for which we would like to make several statements.

We are concerned about illegal logging in Romania as much as the civil society and we want to emphasize that Holzindustrie Schweighofer is not part of the problem, but part of the solution. We advocate responsible woodworking and we are already making all possible efforts that can be made by a company activating in this industry. We are transparently offering information about the traceability of the wood we purchase, we comply with all legislation and we impose to our suppliers to prove the legal origin of the wood they deliver. Moreover, not only do we refuse any suspicious transport of wood, but we also report it to the competent authorities that can investigate and sanction the irregularities. Just within the last year, Holzindustrie Schweighofer has declined and reported over 60 transports of wood with inaccurate documents.

Please access the links below to read our clarifications regarding the allegations brought in the EIA report.

Holzindustrie Schweighofer statement towards EIA report

Holzindustrie Schweighofer clarifications towards EIA report

Holzindustrie Schweighofer appalled by false accusations and dubious procedural methods of environmental protection organisations

At a media conference in Vienna, three environmental protection organisations presented a report on irregularities in forestry in Romania.

This report attempts to present an entanglement of Holzindustrie Schweighofer in illegal dealings, although knowledge of the facts and accurate observation of these facts show that no such dealings or unlawful acts have occurred.

Find the press release of the company with more details on this issue here.

Gerald Schweighofer, named honorary citizen of Comanesti

Gerald Schweighofer, General Director of Holzindustrie Schweighofer, was awarded the title of honorary citizen of Comanesti city. The decision was taken unanimously during a Local Council meeting, due to his contribution to the development of the local economy and community over the past 5 years.

Within only 5 years since the acquisition of the Baco factory in Comanesti, Bacau County, in 2010, Holzindustrie Schweighofer has invested 25 million euro in the upgrading and expansion of this facility, turning it into an internationally renowned business. Following a production increase of 270%, the factory currently has the world’s largest blockboard production in one location. Moreover, 750 jobs were created, as the company is the biggest private employer in Comanesti, and other 3,000 people in the city and surrounding areas rely directly upon the income of the employers working in the factory. Holzindustrie Schweighofer is also the main contributor to the state budget in the area, the factory in Comanesti bringing more than 10 million euro to the state’s consolidated budget during 2011-2014.

Besides the investments in the Baco factory, Gerald Schweighofer has directly involved himself in the development of the local community, offering financial support amounting to 1.2 million euro in the last 4 years to highly important social projects in Comanesti such as: the rehabilitation of the local hospital, which was saved from being closed, the renovation of the building that hosts the Children’s Club, the renovation of schools, kindergartens and day care centers, as well as the construction of social dwellings.

Acquisition of Klausner Holz Sachsen GmbH by Holzindustrie Schweighofer completed

After the contract was signed in August the controls by the responsible statutory authorities were done and finally the antitrust approval was given now on 7th October 2015.

By that Holzindustrie Schweighofer takes over the operational management of the sawmill in Kodersdorf. As announced the employees of the location were taken over.

Sawmill Kodersdorf

Schweighofer Fiber presents its environmental declaration for 2015

Schweighofer Fiber’s extensive environmental programme for 2015 contains numerous measures that are being taken in the production processes as well as with operating the Schweighofer Group’s factory that produces cellulose in the town of Hallein.

Some of the most important measures that Schweighofer Fiber is taking are intended to increase its efficiency in order to face the great challenges of the future and to overcome the competitive disadvantages compared with the manufacturers in South Africa, Brazil and Canada. Many of the measures for increasing its efficiency are motivated by strictly following the company’s motto of ‘Added value from wood’.

Only 40% of the raw wood is typically used for manufacturing the viscose cellulose. Therefore, we are analysing together with our cooperative partners whether the waste lye that accumulates while the viscose cellulose is being produced can be practically recycled for other purposes.

Schweighofer Fiber recognizes the importance of biogas as a by-product arising from producing cellulose. The recent investments in modern technology have enabled the factory in Hallein to generate up to 1,300 m³ of biogas per hour in the meantime. As a result, Schweighofer Fiber is also able to provide green electricity and district heating to thousands of households in the region, besides supplying its own factory.

Environmental declaration for 2015 in German (download)

Schweighofer Fiber

Appeal procedure against Schweighofer’s PEFC certificate stopped

The appeal against the certificate was brought by PEFC Austria on 6 August 2015, based on allegations made by the Environmental Investigation Agency (EIA) and the Romanian Ministry for Environment.

Since the allegations could not be substantiated, PEFC Austria asked the EIA, Neuer Weg, Nostra Silva, Bankwatch Romania, WWF Romania and the Romanian Ministry for Environment to provide evidence to allow the matter to be settled.

However, no information was provided to substantiate the concerns regarding compliance with the PEFC standard.

Moreover, the accreditation body (Akkreditierung Austria) investigated claims of bias and lack of impartiality and objectivity levelled against Holzforschung Austria. This investigation did also not find any irregularities.

See the official information of PEFC Austria here: http://pefc.at/wp-content/uploads/2015/01/Schweighofer-Zertifikat-bestaetigt.pdf

English translation (download)

Holzindustrie Schweighofer present at BIFE-SIM 2015

Holzindustrie Schweighofer will participate in this year’s edition of BIFE-SIM, the International Furniture, Equipment and Accessories Fair, which will take place between September 19 and 23 at Romexpo, Bucharest.

This is the second participation of our company within BIFE-SIM as an exhibitor, and, this year, visitors will be able to see, at our stand, Holzindustrie Schweighofer’s products, fabricated in our the production units from Romania, namely Sebeș, Rădăuți, Siret and Comănești, such as profile boards, laminated products, blockboards, concrete formwork panel, DIY panels, wooden fuel.

Visitors will also be able to find out more details regarding the entirety of our company’s products, the production capacity and the fabrication process, as well as discuss with company representatives.

We are awaiting your presence in sector A, stand no. 301.

The visiting schedule is:

19 – 20 September: 10:00 – 18:00 pm

21 - 22 September: 10:00 - 19:30 pm

BIFE SIM 2015

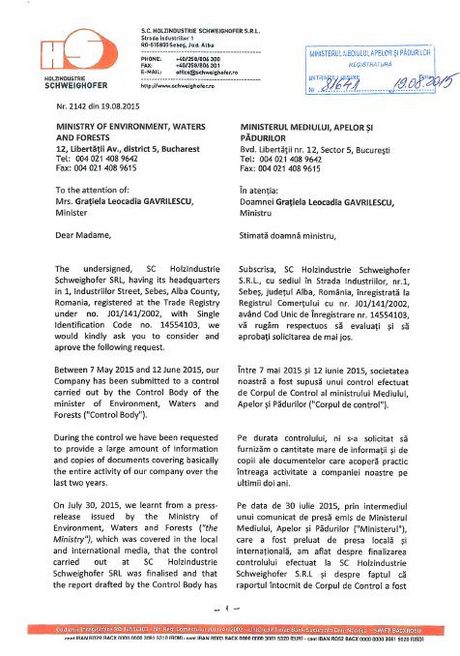

Official request at the Ministry of Environment, Waters and Forests

Regarding the information published by the media in the last days concerning the report the Ministry of the Environment, Waters and Forests drafted following the controls conducted at our sawmills from Sebes and Radauti, we want to underline that Holzindustrie Schweighofer has filed an official request at the Ministry of Environment, Waters and Forests on 19 August 2015, to receive a copy of the report, but it has not yet been provided to us.

The official request can be read here

Holzindustrie Schweighofer starts operations in Reci sawmill

Holzindustrie Schweighofer has started the operation in its newest sawmill in Reci, in Covasna County, after receiving all the permits required to function, this being an important project for the local wood industry, as well as for the local community.

With an area of around 70 hectares and a cutting capacity of 800,000 cubic meters of round wood per year, sourced from sustainably managed forests, the new factory will represent a 150 million euro investment.

Continuing the tradition of being a top employer in the industry, the sawmill in Reci will employ around 650 workers at full capacity, with capabilities to train and qualify employees on-site. Moreover, we expect this new sawmill to create other 2,000 jobs in related industries, based on our experience from the other factories.

Thus, Holzindustrie Schweighofer re-affirms its commitment to contribute to the development of the markets and communities in which it operates by generating professional opportunities for the local labour force and supporting diverse economic activities in these areas.

Key facts and figures – Reci sawmill:

• EUR 150 million investment;

• 650 workers at full capacity;

• 2,000 jobs created in related industries;

• 800,000 cubic meters of wood cutting capacity per year.

Schweighofer Group is buying a sawmill in Germany from Klausner Group

By taking over the Kodersdorf sawmill in Saxony, Schweighofer will expand its capacity in wood industry towards the border triangle between Germany, Poland and the Czech Republic. The main reasons for buying the mill in Kodersdorf were – besides the logistical advantages – the modern equipment and opportunities for expansion that the site offers. The contract of sale was signed recently and it is subject to the responsible statutory authorities giving consent. It is expected that the deal will be closed by the end of September.

The supply of raw materials is very good in the region. The costs of transport can be kept very low due to the central position and the transport connections. Apart from that, the mill has an excellent base of customers and suppliers.

The sawmill has specialized in processing coniferous timber and has a cutting capacity of 1.2 Mio cbm of timber per year. The energy-efficient kiln drying are supplied with heat from its own heating plant. The planing capacity is about 400,000 m³ annually.

About 250 employees are currently working in this mill. It is intended to expand the business during the medium term.

Holzindustrie Schweighofer: PEFC™ certificate confirmed

Results of the advanced audit are available

Holzindustrie Schweighofer fulfils the provisions and directives of the strict PEFC™ standards with respect to checking the origin of the wood.This is the result of an audit of the company that was conducted following allegations made by an environmental protection organisation, and these allegations were therefore disproved.

The "Chain of custody" certification of the internationally recognised organisation PEFC™ guarantees that the wood used or obtained by the company is controlled wood from undisputed sources. In order to consistently prove and ensure this, it is not only the wood-processing plants that undergo strict inspection. For obtaining certification, all the stations of the value chain must comply with a strict set of regulations - from the forest to the sawmill right up to the end product.

Holzindustrie Schweighofer now underwent this strict inspection by independent auditors again after the certification authority demanded an immediate auditing of the sawmill locations of Holzindustrie Schweighofer in Romania, due to a critical report by an environmental protection organisation.

We now officially have the result of this special audit, which confirms that Holzindustrie Schweighofer has executed the provisions of the PEFC CoC standard for the wood procurement. The certificate (HFA-CoC 0018) has thus been verified.

Gerald Schweighofer: "The audit completed now once again verifies that our company meets the international standards. The allegations of an environmental protection organisation have proved to be unfounded and been entirely disproved. Numbers, dates and facts as well as the evaluation by the external auditor have confirmed clearly and most recently that in order to ensure the legality of the origin of the processed wood, we employ the most stringent control mechanisms.

As a part of the inspection, on-the-spot checks were conducted at company locations in Austria and Romania from March 2015 to June 2015.

7th Schweighofer Prize awarded in Vienna

- The winners come from Austria, Germany, Sweden, Italy and Switzerland

- Over 700 visitors from 41 countries from the international wood sector and representatives from the fields of research and economy took part at the celebration

- EUR 300,000 for innovative ideas concerning wood

Gerald Schweighofer awarded the prizes in the presence of Austrian Federal Minister for Agriculture and Environment Andrä Rupprechter, Austrian Federal Minister for Labour and Social Affairs Rudolf Hundstorfer, as well as Vienna’s Mayor Michael Häupl.

Projects, products and technologies from Germany, Sweden, Italy and Switzerland received an award. Dr. Erich Wiesner, CEO of the Wiehag Group, received the main prize for his life’s work.

Supporting next generation researchers. This year for the first time, the Schweighofer Prize established a cooperation with one of the largest integrated forest products companies in the world; the North American company Canfor. According to the motto “From Knowledge to Innovation”, 27 young researchers from a total of 16 countries (amongst them Romania) exchanged ideas under the leadership of Schweighofer Prize jury chairman Prof. Dr. Alfred Teischinger (University of Agricultural Science) in the domed hall of the TU Vienna.

Information concerning the winners – www.schweighofer-prize.org

Holzindustrie Schweighofer provides materials for Design Fair in Basel

The company takes part in this year's Design Miami/Basel in Switzerland – cooperating in a special way with the renowned architect team of Olson Kundig (US). Based on the plans of Olson Kundig the Collector’s Lounge of the 10th design fair was realized in the form of a cube. This so called “Outpost Basel” combines diverse geographical, material and cultural elements from Japan, Austria, Romania and America. An outstanding presentation of wood in new and completely unexpected forms.

From a distance, the object looks like a simple dark cube. The construction consisting of plates and wooden bricks demonstrates very clearly how innovative and versatile this natural product can be. As a tribute to the 10th Anniversary of Design Miami/ Basel the exterior of Outpost Basel is covered with a repeated X-shaped pattern. But when visitors walk closer, the construction of wood with a height of 6.4 meters reveals its true purpose: an X-shaped iron door leads to stunning lounge and restaurant area.

Olson Kundig Architects - www.olsonkundig.com

Press release

Schweighofer initiative

On www.schweighofer-initiative.org we offer background information, answers to the most frequently asked questions and we state our point of view. The content will be extended constantly. We also want to encourage all interested people and NGO’s to get in contact with us. You will experience our everyday work and our corporate philosophy. We are determined to show our attitude towards responsible use of wood as a natural resource. We feel obliged to do so - towards our employees, forestry, the timber industry and the interested public For many years, Holzindustrie Schweighofer has been a pioneer in sustainable and responsible wood processing.

Because we work with and depend on wood.

Holzindustrie Schweighofer writes open letter to members of Romanian National Security Council – CSAT

Holzindustrie Schweighofer strongly supports any measure of preventing illegal logging and ensuring a sustainable forestry system in Romania. We appreciate President Iohannis’ targeting of this problem by now involving the Romanian National Security Council (CSAT), an independent body free of special interests in the forestry industry. This independent analysis of the current situation is essential and offers a path to practical recommendations based on correct facts and figures and in line with international laws.

In order to foster a transparent discussion, Holzindustrie Schweighofer has sent an open letter (Link) to all members of CSAT, informing them of our deep concerns regarding the first draft of modifications to the Forestry Code in Romania. In the draft initially passed by the Parliament, this legislation would breach several international trade and investment agreements as well as infringe the EU competition law.

Our letter also sought to explain how an unbalanced approach to illegal logging and the short-sighted market limitations, arisen out of special interest groups, would destroy thousands of jobs all over the country and put Holzindustrie Schweighofer’s future investments as well of those of new potential investors in Romania in harm’s way. A legislation which is in clear violation of international laws would jeopardize Romania’s credibility as a competitive host country for investors worldwide.

Holzindustrie Schweighofer has never intended to threaten the Romanian Government of international litigation. Holzindustrie Schweighofer stands ready to defend and protect our rights as a market participant but also those of our Romanian employees and partners and their families.

If the Romanian Government, and particularly the CSAT, is unable to dissuade the Parliament from excluding aspects of the legislation that violate existing international treaties and European competition law, any foreign investor in the forestry sector will have no choice but to undertake efforts to protect its investment under the law.

Holzindustrie Schweighofer stands ready to provide additional information to CSAT upon request in order to assist its independent decision-making process.

A personal statement of Gerald Schweighofer

Following unproven accusations of an NGO, which is wrongfully communicating that Holzindustrie Schweighofer is buying illegal wood, Gerald Schweighofer takes a stand in a very personal Video message.

Gerald Schweighofer: „Our company and employees have been subject to severe accusations over the past few days. It is claimed by an NGO - of all things - that we put Romanian woods at risk by using illegal methods. This is not true and hence, I choose to speak up in this way.

For many decades now, Holzindustrie Schweighofer has been a pioneer for sustainable and responsible wood processing. And I also want to say why we are so committed: wood is our livelihood. As a family business it would be totally wrong for us to destroy this resource. We are at the forefront to prevent illegal logging, support the fight against the destruction of forests and we are certified according to internationally recognized standards such as PEFC™. We only process wood with registered documents of origin.

We have put in place seamless controls and monitoring in order to ensure this. We check the documents of origin at the gates of our sawmills. The delivery only gets on site if the legal origin has been duly proven. This is how we ensure that only legal and documented logs are supplied and processed. We totally refuse wood from National Parks - even though it is legal from certain regions according to the Forestry Law. Every supplier who does not adhere to our rules or who breaks the law loses his contract with us and the deliveries are not accepted.

A video which is currently doing the rounds online shows my employees filmed with a hidden camera. As you can see this video has been edited. My employees assured me that they have told the alleged customer that we only purchase legal wood. We have asked the producers of this film several times to provide us with the original material. I trust my employees, however, I have suspended the member of staff who is responsible for these conversations until the full facts are established.

I would like to invite all independent environmental organisations to meet me to discuss on how we can advocate together the conservation of forests and promote sustainable forestry. Because I am wholeheartedly committed to this goal.“

Clarification of Holzindustrie Schweighofer regarding a recent TV report in Romania

Clarification of Holzindustrie Schweighofer regarding a recent TV report in Romania and following media reports accusing our company of accepting wood from illegal sources:

-

Holzindustrie Schweighofer is and has always been strictly committed to responsible wood processing. The company strongly rejects all accusations that it is supporting or a benefiter of illegal wood trading. The contrary is true. Illegal wood trading is damaging the forest and the established wood industry.

-

Holzindustrie Schweighofer, in its very own interest, therefore supports and lives sustainability, has a well-established and extensive origin control system, is quality certified by renown independent institutions (PEFC™), and processes only registered wood with documents of origin that fulfil all legal requirements of Romania and the European Union.

-

Statements of a company employee presented in a recent video material published by EIA have been massively shortened according to the involved employees, presented in a false context and is therefore misleading and providing wrongful information.

-

Nevertheless, we already started a re-check of all internal processes and suppliers, to – once again – prove and ensure that the highest environmental standards are met company-wide, now and in the future. The results will be transparently published and are subject to discussion with environmental organisations and public authorities.

Recently, some media in Romania have taken over unproven accusations of NGOs, accusing our company of inappropriate activities in the field of wood harvesting and purchasing and also questioned the company’s relations to public authorities in Romania.

Holzindustrie Schweighofer has been at the forefront of responsible wood processing for decades and is certified by independent, worldwide renown and accepted institutions, such as the Programme for the Endorsement of Forest Certification (PEFC™).

We are therefore truly shocked about the recent unqualified attacks and wrongful reports about our company. Therefore, we would like to inform about the following facts and state clearly:

-

Any wood delivery to Holzindustrie Schweighofer has to be sourced from legal harvesting only. All our suppliers are contractually committed to that in their purchase contracts and – additionally – the fulfilment is controlled with legally binding documents at each delivery at the gates of our company. All suppliers must strictly obey these obligations in any case – otherwise they are liable to legal prosecution and can be sued for damages.

-

We strictly refuse to buy and process any wood from national parks (even though it is legal according to the forest law).

-

Holzindustrie Schweighofer fulfils all legal obligations, contractually commits suppliers to fulfil their legal obligations and has established internal control processes in addition. We co-operate with the authorities responsible for controlling and fighting against illegal wood harvesting and trading – and we are in favour of implementing even more efficient controls directly at harvesting sites and transport routes.

-

We have permanent and regular controls by the responsible authorities in all our mills. We are always transparently providing the necessary documents required by Romanian law and EU regulations for proving the legal provenience of the wooden materials we purchase. Despite other reports, Holzindustrie Schweighofer subsequently is not involved in legal cases about illegal wood purchase.

-

To prevent further wrongful accusations and prove publicly our high quality standards, Holzindustrie Schweighofer started a re-check of all internal processes and suppliers. The results of these re-checks will be published very soon and will be also provided to the responsible authorities and certification bodies.

-

We invite NGOs interested in and fighting for sustainable wood processing to directly contact us for further information. We are looking forward to a level-field dialogue and we are open to co-operations in the field of sustainability, which is clearly an area of common interests of NGOs, our company and the general public.

Gerald Schweighofer

Owner of Holzindustrie Schweighofer

This year Schweighofer Fiber celebrates “125 Years Cellulose Hallein“

To mark this occasion, a celebration took place on 24 April in the plant with numerous honorary guests in attendance from politics, industry, government agencies, social partners and interest groups. Owner Gerald Schweighofer and managing director Jörg Harbring extended the invitations to this celebration. A big highlight was the opening of a special exhibit which shows how the cellulose and paper mill has influenced the development of the city of Hallein.

Press release

Holzindustrie Schweighofer BACO at Interzum 2015

Interzum is the leading international trade fair and meeting point for furniture production and interior design, taking place between 5th – 8th May 2015, in Cologne.

This year’s focus of Holzindustrie Schweighofer is the new production line in Comăneşti - the World’s biggest blockboard production in one location - , as well as its products and innovations.

We are looking forward to meeting you in hall 5.1, stand no. 059.

Interzum 2015

CLT office building in the new Schweighofer sawmill in Reci

The office building in the new sawmill was built in the modern CLT design (cross-laminated timber). Amongst others, the reasons for using the CLT design are

- the enormous interior design flexibility

- the dry and fast way of construction and

- best heat insulation characteristics

Moreover, the wood-based material ensures high sound absorption and fire safety.

Altogether, about 670 m³ glued laminated timber were used for the currently biggest CLT building in Romania. Additionally, an insulation of 20 cm was installed. The shell construction without insulation merely required 15 days. Now, the interior construction is taking place – the employees should move into the building in mid-May 2015.

New reloading point for pellets at Schweighofer Fiber in Hallein

At the beginning of May the new reloading point at the Schweighofer Fiber plant is going to start operation – with the help of a fully-automated filling station, pellets can be pumped as required from the silo onto trucks by pellets dealers. Pellets and fuel dealers can benefit from this new reloading point because they can pick up the amount as needed and deliver it to their end clients

New BEAM production begins in the Radauti saw mill

After the test period the new Schweighofer gluelam plant received the necessary JAS certificate (Japan Agriculture Standard) and went into operation in February. BEAMs are made by gluing together strength-tested lamellas in a specially required structure, this ensures an homogenous stability. They are used for horizontal applications in traditional Japanese wooden houses. 100.000 cbm JAS certified redwood BEAMs (standard E105-F300) will be produced annually in Radauti and exported to Japan. At present Holzindustrie Schweighofer is the only company in Eastern Europe, that produces BEAMs for the Japanese market. An exclusive contract was signed with Lamsell Corporation (Meiken) for sales in Japan.

Schweighofer invested 14 m euros into the new plant in Radauti, 75 additional work places will be created for the long term.

Radauti saw mill

Survival help for winter

Holzindustrie Schweighofer financed windows for a day care center for children in Ukraine

Due to the fights in the eastern part of Ukraine last year, a lot of people became homeless and had to seek shelter with relatives and in emergency accommodation. Caritas Vienna organised a relief campaign, in order to provide buildings with windows and to save people from freezing. Holzindustrie Schweighofer supported this activity with 30,000 euros. Among others a day care center for children in Slowjansk was repaired. The children were very happy that they could return to their house and sent their personal thanks to the company.